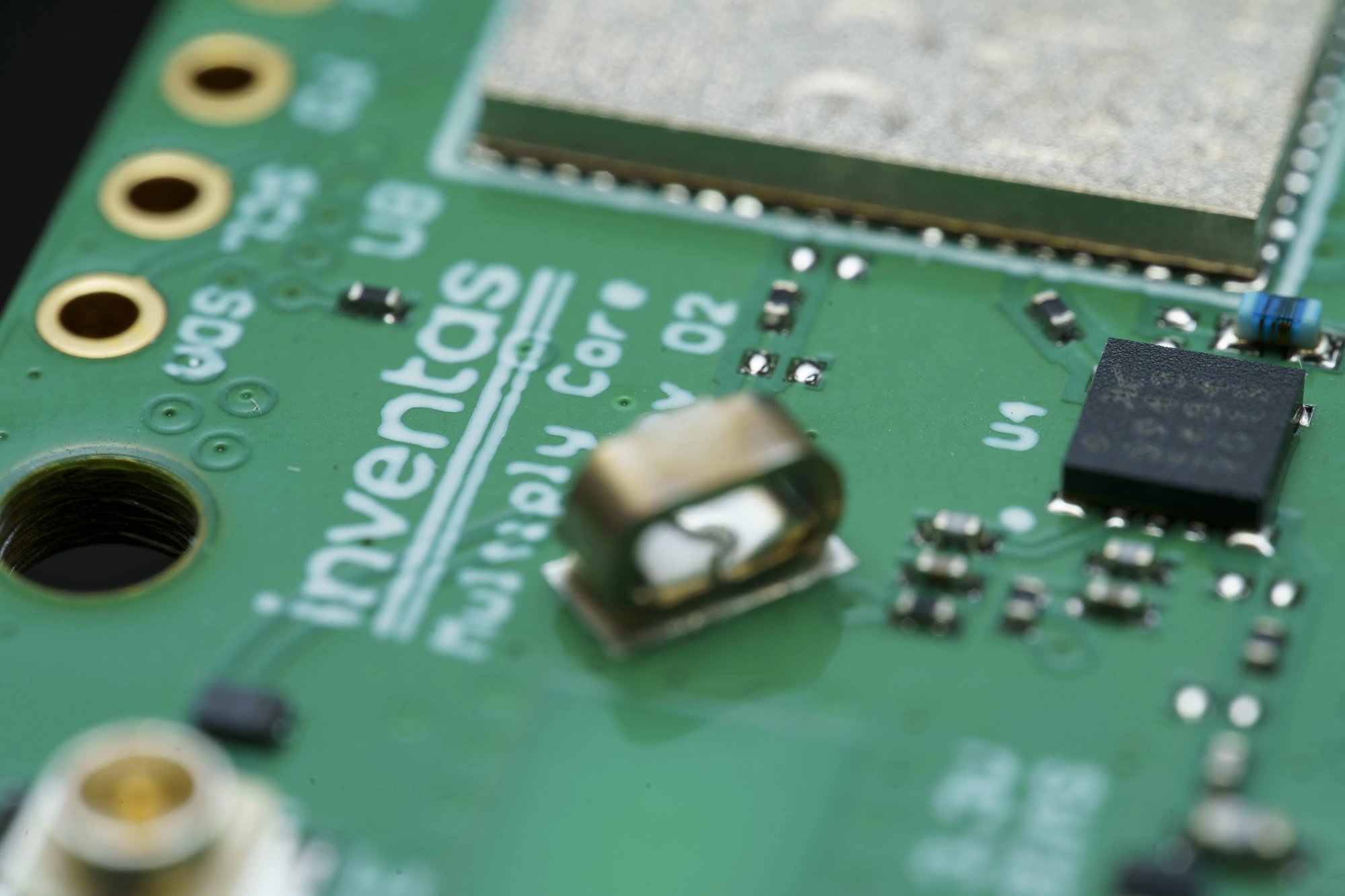

Hardware development – From idea to finished circuit board

When creating solutions and products that run on batteries or are powered in some other way, it is almost inevitable that a circuit board will be involved. In many cases, you can get by with an existing circuit board that can be customized with your own software. However, there is often a need to develop something custom-made, to get the solution exactly how you want it at an affordable unit cost.

The tools we use

Inventas adapts to the customer's needs if specific EDA tools must be used, and we have experience with most of the major tools. In cases where this is open, we use Altium Designer and KiCAD.

In addition, Inventas has electronics labs in most of our offices, with equipment for examining, testing and modifying circuit boards. We also have pick-and-place machines for the production of small series in cases where it is more practical than using an external manufacturer.

Our methodology

We work according to a structured and iterative process when developing printed circuit boards, and see documentation as just as important a part of the development process as the design itself. We also have close dialogue with the customer along the way to ensure that the focus is always right. The basic process we follow for the actual PCB development is shown in the figure below.

.png?width=1825&height=1071&name=Frame%2018212%20(1).png)

Interdisciplinary collaboration

An essential part of the development is the involvement of other of our electronics engineers than the one or more who are the main developers on the project. This is done primarily for reviews/sideman control, but also for sparring on technical challenges. Good collaboration helps to ensure a fast path to good technical solutions, and a consistent level of quality.

Each project is different, and may need adaptation or additions to this process. In cases where the customer has their own process and document system to be used, we follow it.

We contribute with:

We can take on the entire development process, or parts of it. Some examples of how our professionals can contribute are:

- You have an idea and need hardware for proof-of-concept.

- You have a circuit board that is not working optimally. We can troubleshoot and develop the next version.

- You have the first version of a circuit board and need it to be adapted for mass production.

- You have a development team, but need extra capacity for a period of time. We can hire out an electronics engineer who can either be on-site at your company or work remotely from us.

With our combined expertise, it is highly likely that we have encountered something similar to your problem. At the same time, our flexibility allows us to adapt to your workflow.

Contact us

Fill out the form and contact us to arrange the details.

Ready to get your idea to a finished circuit board?

Knut Nilsen

knut.nilsen@inventas.no

90 84 44 68

Trude Forsbak

trude.forsbak@inventas.no

45 23 89 60

Marius Elvegård

marius.elvegard@inventas.no

99 03 22 56