Simulation-driven product development

When a product is to be used in a demanding environment, simulation is often a good tool. to ensure a efficient and safe design.By using simulations, we gain insight into how different loads affect structures and how the structures must be designed to withstand them.

Different simulations:

With simulation-driven product development, we make frequent iterative simulations and design changes. This means we can simulate, improve and simulate again. This means fewer prototypes and zero series that fail test requirements are needed. When loads, temperatures and boundary conditions affect the design, our engineers can find solutions faster with the help of simulations.

Inventas performs calculations in two main areas: solids and liquids. For solids, we use the finite element method (FEM), and for liquids, we use computational fluid dynamics (CFD).

How simulation will influence future product development

Structural calculations

Finite Element Method (FEM)

Calculation programs such as ABAQUS and NX have made advanced FEM (Finite Element Method) more accessible than ever. Our experts not only know the software packages, but also understand the underlying physics and equations. This also applies to advanced materials (rubber, polymers, composites), contact calculations and vibrations.

Simulation-driven design

Simulations can be used throughout the development of a product. Right from the start, they can help choose the right concept, and can be used to support various design choices. It is especially useful to be able to make rapid iterations without having to produce prototypes and perform physical tests.

We perform:

-

Early-phase evaluation of concepts (feasibility study and cost estimate).

-

Hand calculations and design calculators for rapid evaluation of concepts.

-

Iterative design calculations.

-

Topology optimization that allows us to generate lightweight but rigid designs.

Capacity calculations

We perform analyses to check whether a detailed design has sufficient strength in relation to the criteria in a design standard. This allows us to verify the design before it is put into production or to uncover vulnerable areas that should be reinforced.

Typical investigations we perform are:

-

Limit state calculations of steel and aluminum structures

-

Breaching load in cast iron, polymer and composite materials

-

Functional calculations

-

Service condition (deformations)

-

Buckling

-

Bolt calculation

-

Welding investigation

We often work with approval against various standards such as DNV, Eurocode, Norsok and ASME.

Shock and vibration analyses

For many products, shock and vibration loads are critical. Typical test requirements can be precisely recreated with modal dynamics simulations. These simulations allow us to evaluate whether the design is sufficient already in the early stages. This is important because it is often very difficult to solve challenges with vibrations later in the development process. Vibration calculations and are also relevant in, among other things, the design of ultrasonic equipment and the assessment of fatigue.

We can help you with, among other things:

-

Meet test requirements ("Digital shake table")

-

Design of components exposed to vibration

-

Choosing the right solution for damping and isolation

-

Assessing shock resistance in critical components

-

Ensuring service life under harsh operating environments

Advanced Materials

Metals, and especially steel, are well-known in structural design. Their use is therefore well supported by standards, and relevant material data is often available. The use of other materials can present challenges, especially in the design of load-bearing components where mechanical properties are important.

In addition to metals, we have experience with structures made of materials such as:

-

Composites/laminates

-

Plastics

-

Rubber

-

Glass

Nonlinear simulations

Most structures are usually subject to little deformation and damage during use. In such cases, linear analyses are typically sufficient and most effective.

We also have expertise in the use of nonlinear simulations, which are essential for investigating more complex issues such as:

-

Structures that are subjected to large deformations or plastic deformation where redundancy or ultimate limit state is important

-

The structure is subjected to transient loads such as crashes, slamming, drop tests or cyclic loading

-

Contact between different parts forms part of the load

-

Temperature effects on the material or thermal expansion play a role

Numerical flow calculations

Computational Fluid Dynamics (CFD)

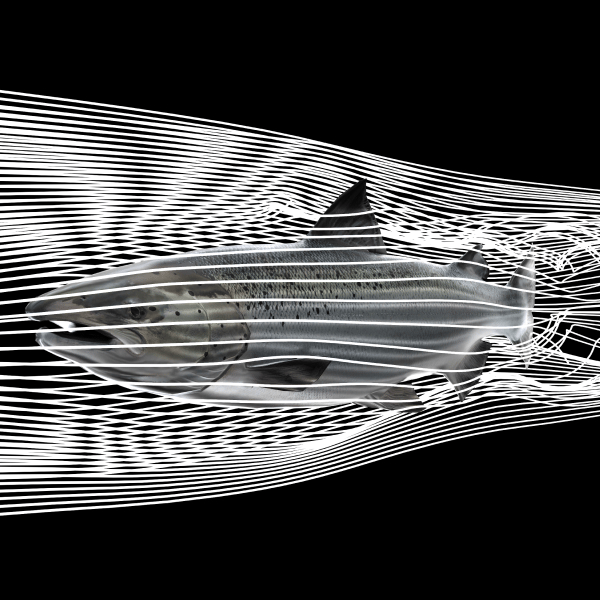

CFD (Computational Fluid Dynamics) is a combination of engineering mathematics and fluid dynamics that enables calculations of complex technical problems.

Air, liquid, and heat transport are not always intuitive to reason about, and therefore powerful simulation tools are often invaluable in the development phase of products. Our method and working methodology allow us to simulate many load cases and geometry proposals so that we can quickly suggest design improvements.

Thermal calculations

CFD simulations can model heat transfer in a product due to convection, conduction, and radiation. By understanding how heat flows through a device, we can optimize cooling solutions and thus avoid overheating.

Thermal calculations are often used in the following ways:

-

Evaluating heat sink designs

-

Component temperature monitoring

-

Identify and improve thermal bottlenecks

-

Selection and placement of fan/filter

-

Optimize ventilation solutions and internal layout

-

Avoid derating electronics

-

Flow of water and oil in cooling blocks

Aquaculture

CFD simulation of aquaculture systems provides the aquaculture industry with a basis for making better informed decisions, thereby contributing to a more sustainable and profitable business. More specifically, CFD can assist in a better understanding of the following:

-

Internal flow rates in the cage

-

Solutions for water circulation and thruster selection/placement

-

Pump selection for main and auxiliary systems

-

Interaction between waves and cages

-

Inlet and outlet flows. Evaluate valves and pressure drops

-

Optimizing feed distribution in the fish cage

Pipe flow

Piping system designs can be investigated and optimized using CFD simulations. At Inventas, we help our customers understand the following by simulating flow through intricate piping networks:

-

Pressure loss through the piping system

-

Flow distribution along parallel paths

-

Temperature and cooling of fluids through heat exchangers and cooling blocks

-

Two-phase flow (for example, steam in vapor/liquid form)

-

Pump selection

-

Selection of pipe diameter

-

Optimize piping design to relieve or downsize pumps

-

Identify areas of turbulence, cavitation or "dead zones"

Water treatment plant

CFD can help optimize the design and operation of treatment processes in the water treatment industry. Inventas simulates fluid flow and particle transport within treatment plants, delivering valuable insights into:

-

Surface flow velocity and other critical areas of interest

-

Optimize pollution removal

-

Improve treatment efficiency

-

Optimize dosing strategies

-

Minimize waste production

Do you develop in a demanding environment and want to ensure an efficient and secure design?

Our experts have both extensive experience with calculations and extensive professional education. With us you will find the country's best environment for advanced simulations and analyses. We hire consultants or include simulation in product development. Fill out the form and contact us to arrange the details.

Curious about simulation-driven product development?

Kristoffer Brinchmann

kristoffer.brinchmann@inventas.no

93 68 59 78

Anders Fosså

anders.fossa@inventas.no

98 84 90 56

Snorre N. Bache

snorre.bache@inventas.no

90 08 32 70